Home

Nikon SA-21-->30

Notes for the

safe

using

of the modified SA-21 Adaptor

Nikon IA-20 (S)

Service

and maintenance?

Downloads

Contact

|

The Nikon roll film Adaptor, the SA-30,

can scan 2 to 40 frames in a continous length, where the SA-21 film

strip adaptor

only scans 2 to 6 frame film strip lengths. The SA-21 is the adaptor

you get as standard with both the

Nikon Super Coolscan 4000ED and the Super

Coolscan 5000ED

(for un-mounted film strips)

An SA-30 adaptor can only be bought as an accessory and costs

the unbelievable amount of 630 EUR! (in Germany)

On rare international internet auctions, the SA-30 adaptors are seldom

found, but when they are, are beyond the 300 EUR mark.

For the occasional scanning of full film strip lengths, these

prices are too high.

There is another way:

Modify your Nikon

SA-21 adaptor with these instructions

When you modify your SA-21 adaptor to operate like an SA-30:

- Your modified SA-21

adaptor has

all the functions of an original SA-30 adaptor.

- The modified adaptor can be used with the same

operating systems and all the

kinds of scansoftware

as an

SA-30 adaptor would.

- There is no loss of your original SA-21adaptor

functions.

(similarly, film strips of only 2

frames minimum can be used)

Note.

The modified Adaptor can be used only with a Nikon Super

Coolscan 4000 ED or Nikon Super Coolscan 5000 ED!

The alteration other types (ie Nikon LS 2000, Nikon

Coolscan

IV ED and V ED) is not possible because of technical

limitations.

Be advised that with this modification,

the adaptor´s manufacturer warranty will be voided.

I must also inform you, that I cannot provide any warranty or take any

responsibility for the adaptor or its functionality.

If you think that you

can´t modify your adaptor by your self, I can do it for you at a

moderate cost, but only within Europe.

Contact

me by

e-mail. I apologize to those outside Europe, but taxes and shipping

costs overseas are to high. I may be certain

you find some one who can do it for you.

To upgrade the Nikon

SA-21 adaptor to function like an SA-30, you will need the following

items:

1. A Philips precision screwdriver (watchmaker size). Check that

the

screwdriver fits to the screw on the bottom of the adaptor.

Some

screws might be tighter than you expect, so make sure it has an

excellent fit.

2. A slightly larger Philips screwdriver (small hand-worker size)

3. A single slit screwdriver of about the same size.

4. A fine soldering iron (max. 25 watts) and

5. Electrician’s solder.

The alteration will take about 1½ to 2 hours

to

complete.

(I have been able to do it in an hour, including

testing, both before and after. Please take into account,

however,

that I have done this many times)

All you will need to do is carefully disassemble,

solder two points together, and reassemble.

Full instructions and pictures here will make it a breeze for you.

Make sure that you have all the suggested

tools

ready in front of you before start. The

very small screws can not be screwed in and out too many times.

Read these instructions completely, and especially note my suggestions

at the end.

1/ Open the adaptor as if it were cleaning.

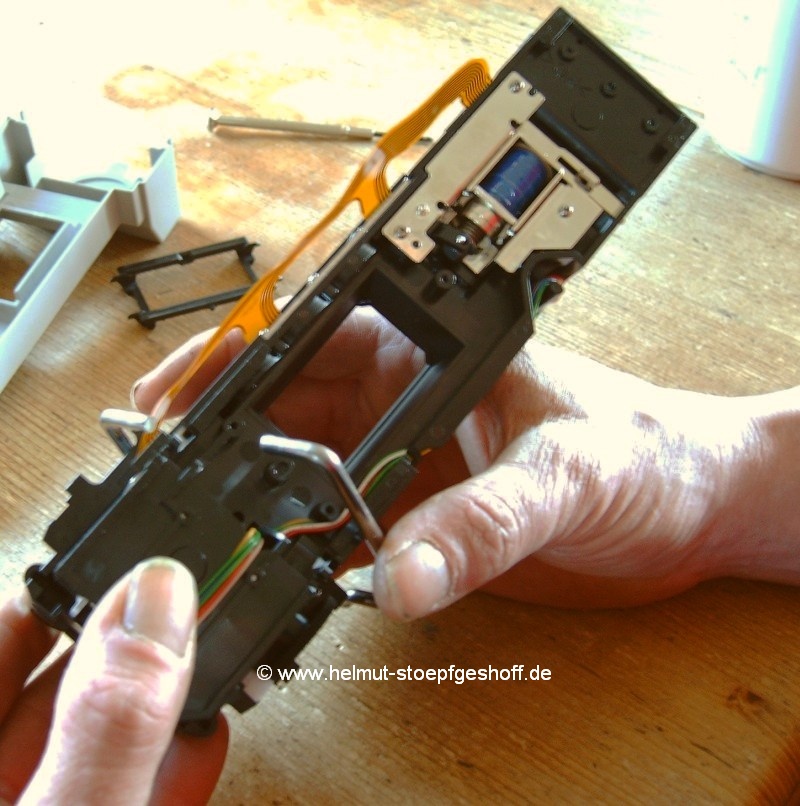

2/ Push the locking bar to open position, and hinge up the top roller

assembly (the bridge) to vertical position.

3/ Carefully lever the top roller assembly (the

bridge) from its hinge pin and keep it safe for

later. This “bridge” has an open slit in the hinge-socket which

allows

you to remove it easily from the pin. Note - do not bend the “bridge”

out of

shape or it may not align back to the hinge-pins. 3/ Carefully lever the top roller assembly (the

bridge) from its hinge pin and keep it safe for

later. This “bridge” has an open slit in the hinge-socket which

allows

you to remove it easily from the pin. Note - do not bend the “bridge”

out of

shape or it may not align back to the hinge-pins.

You will need to remove the angled metal strips (pressure springs)

located above and below the scanning hole.

You will need to remove the angled metal strips (pressure springs)

located above and below the scanning hole.

4/ Take the small Philips screwdriver and remove the two black

screws holding them. The pressure springs hold the loading

track in position.

5/

Now

you can remove the loading track. Please look very carefully at

the loading track, at the pins on the right and the left hand side,

which hold the track in place. They are different sizes. This

means

that it only fits in one way. 5/

Now

you can remove the loading track. Please look very carefully at

the loading track, at the pins on the right and the left hand side,

which hold the track in place. They are different sizes. This

means

that it only fits in one way.

Warning!

Underneath the loading track, a light-sensor can be seen (on the side

where the screws are closer together and closer to the opening).

Please do not touch or scratch this sensor! Any damage to this would

mean that the adaptor can no longer position the film strips correctly.

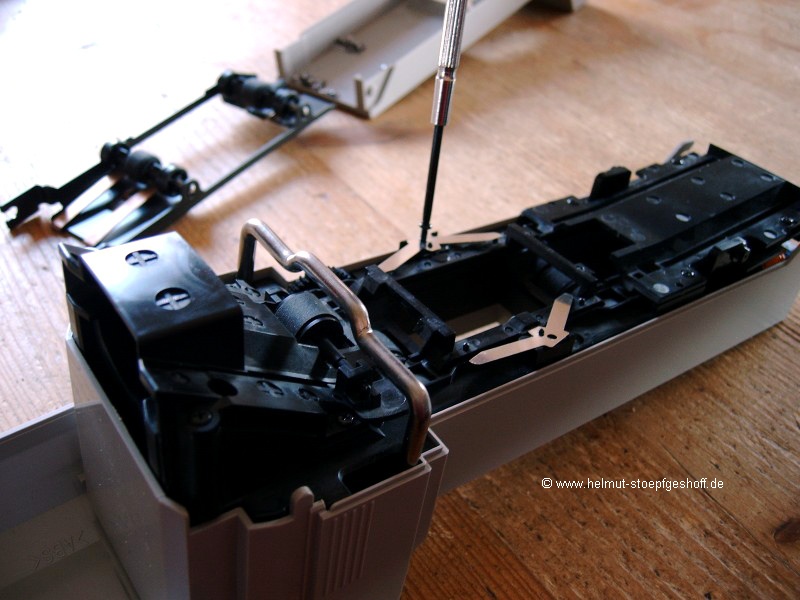

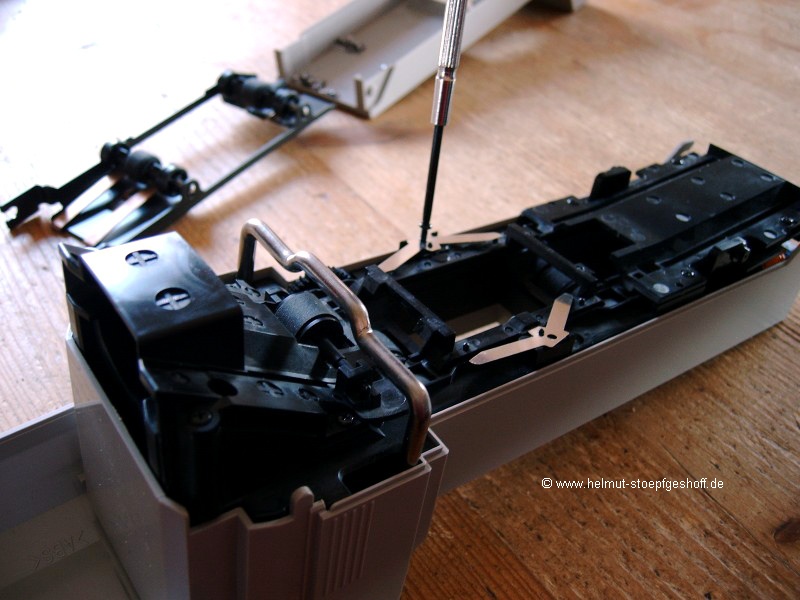

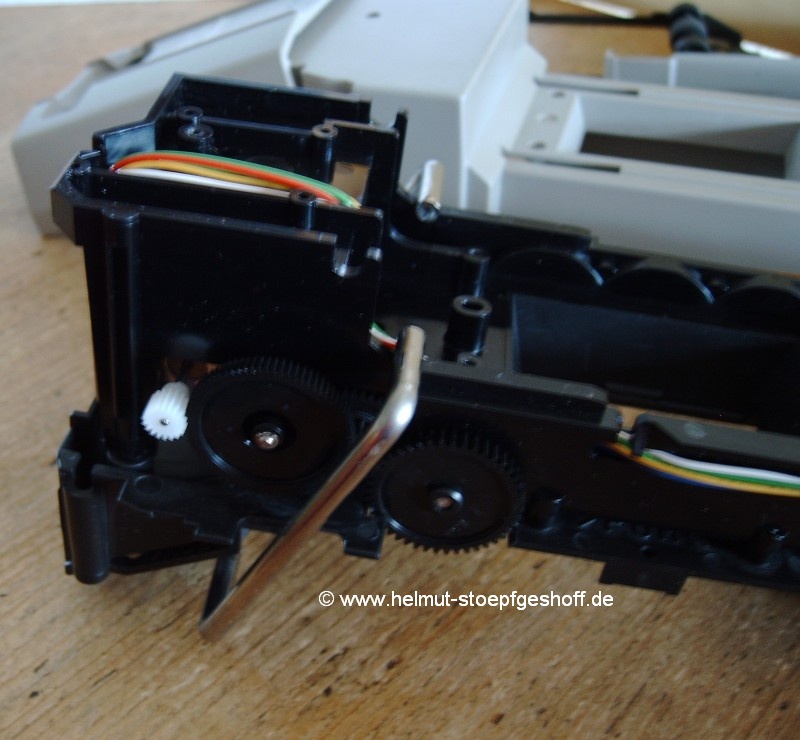

6/ Now, turn the adaptor over, and remove all six screws on the

bottom.

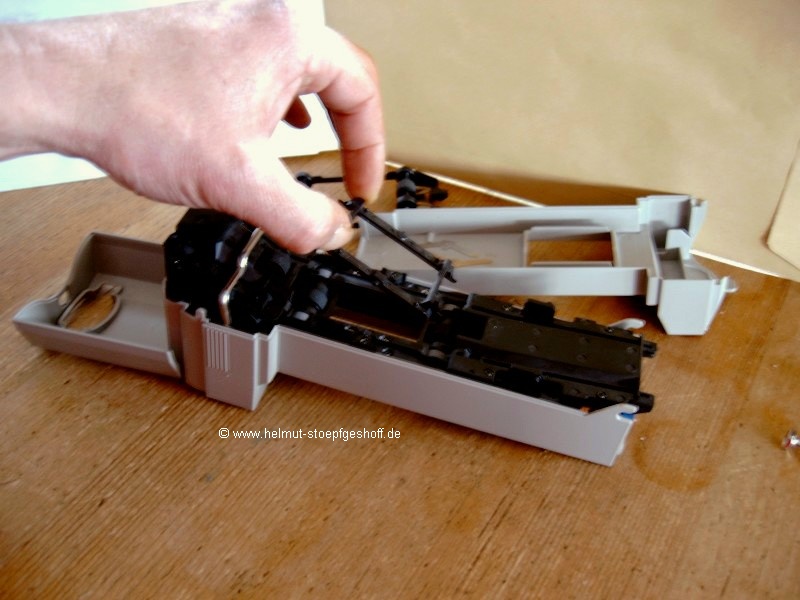

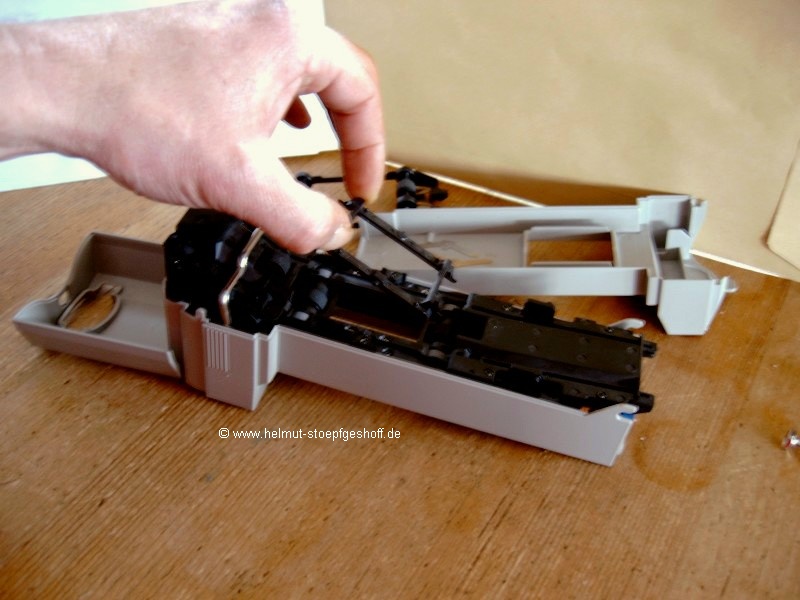

7/ Carefully lift the black assembly out of its grey plastic shell.

Now

you can see that the locking bar for the top roller bridge is open at

the

bottom. Pivot the bar (as if in roller assembly "open" position), and

lift the bar so both hinge ends come out of their pivoting socket

toward the direction of the smaller end of the adaptor. At the same

time, turn the “bracket” a little so that it can be

released from its tilt limit guides. Now

you can see that the locking bar for the top roller bridge is open at

the

bottom. Pivot the bar (as if in roller assembly "open" position), and

lift the bar so both hinge ends come out of their pivoting socket

toward the direction of the smaller end of the adaptor. At the same

time, turn the “bracket” a little so that it can be

released from its tilt limit guides.

(When reassembling, the orientation of the locking bar

is not important as it is

completely symmetrical. All you will need to remember is that it

is the right way around, has to be loaded firstly into the tilt limit

guides, so that it will then

later fit into its pivot point socket. This is not very

difficult. The “locking bar” does not stay easily into its socket

when the adaptor is turned over when returning to the grey plastic

shell.)

(When reassembling, the orientation of the locking bar

is not important as it is

completely symmetrical. All you will need to remember is that it

is the right way around, has to be loaded firstly into the tilt limit

guides, so that it will then

later fit into its pivot point socket. This is not very

difficult. The “locking bar” does not stay easily into its socket

when the adaptor is turned over when returning to the grey plastic

shell.)

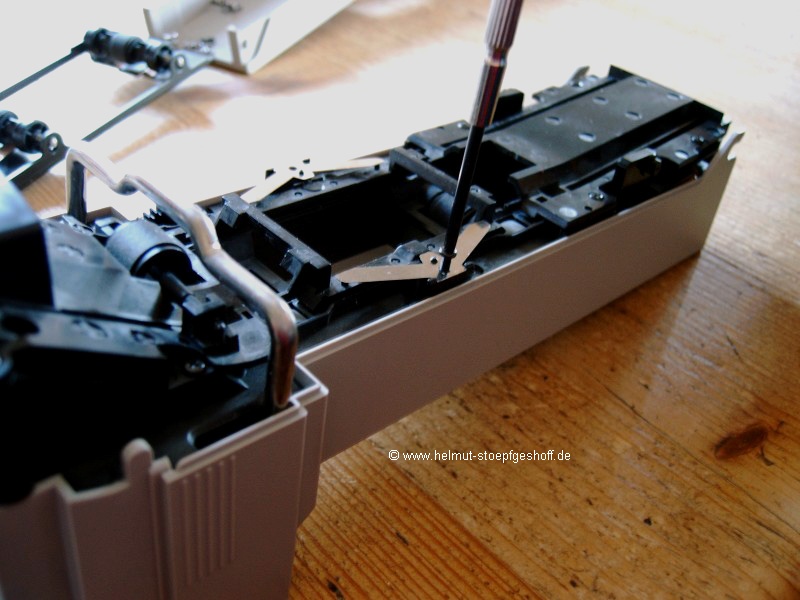

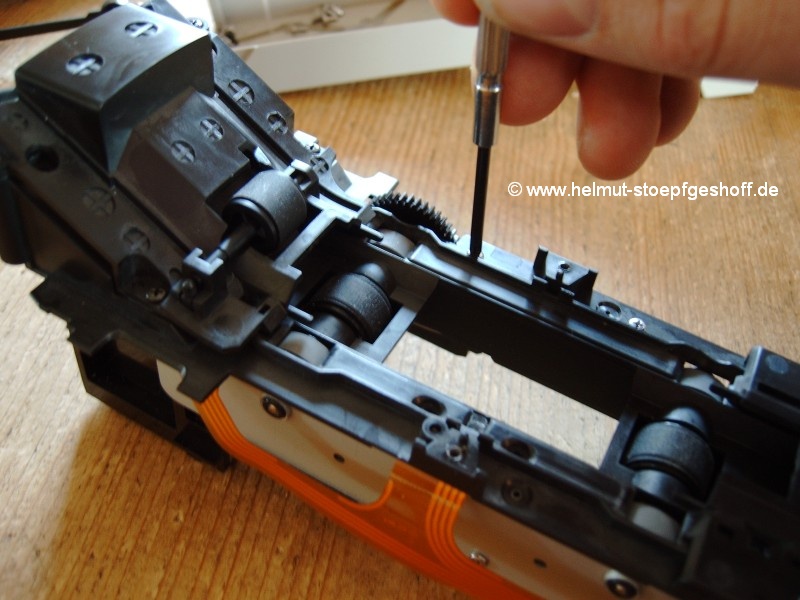

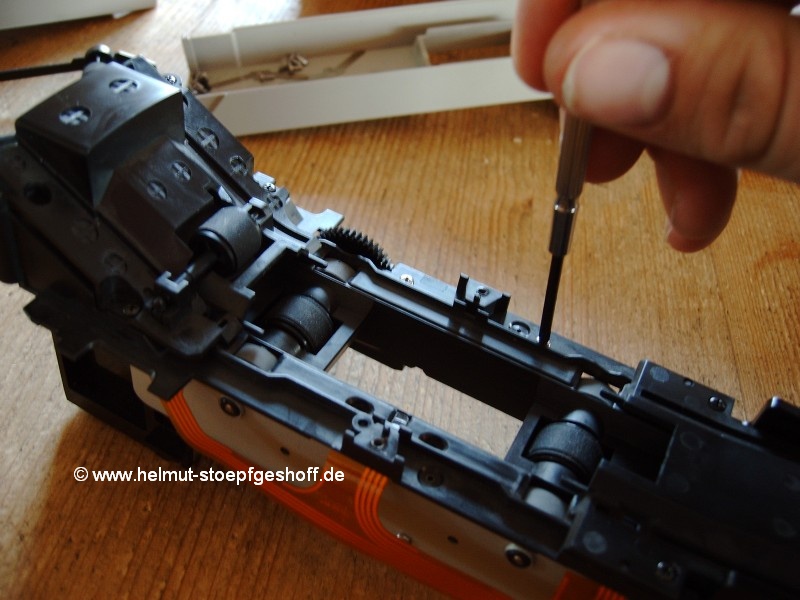

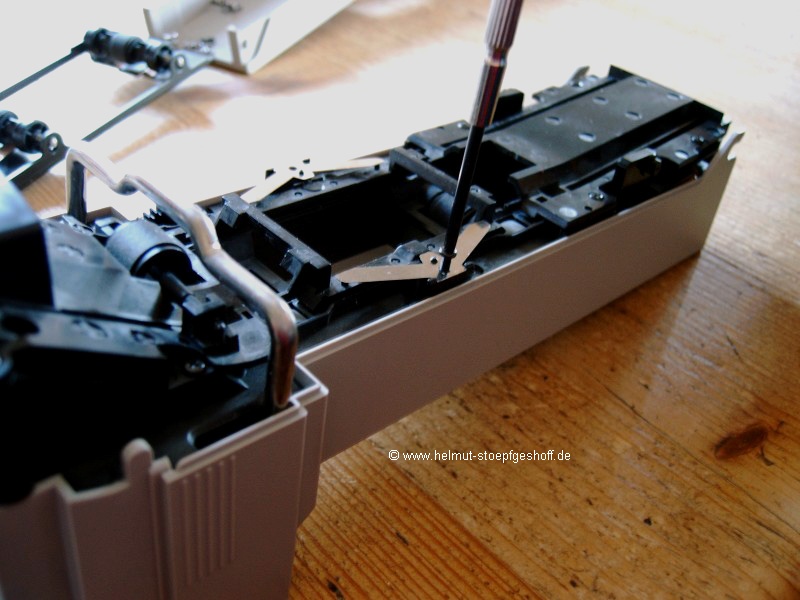

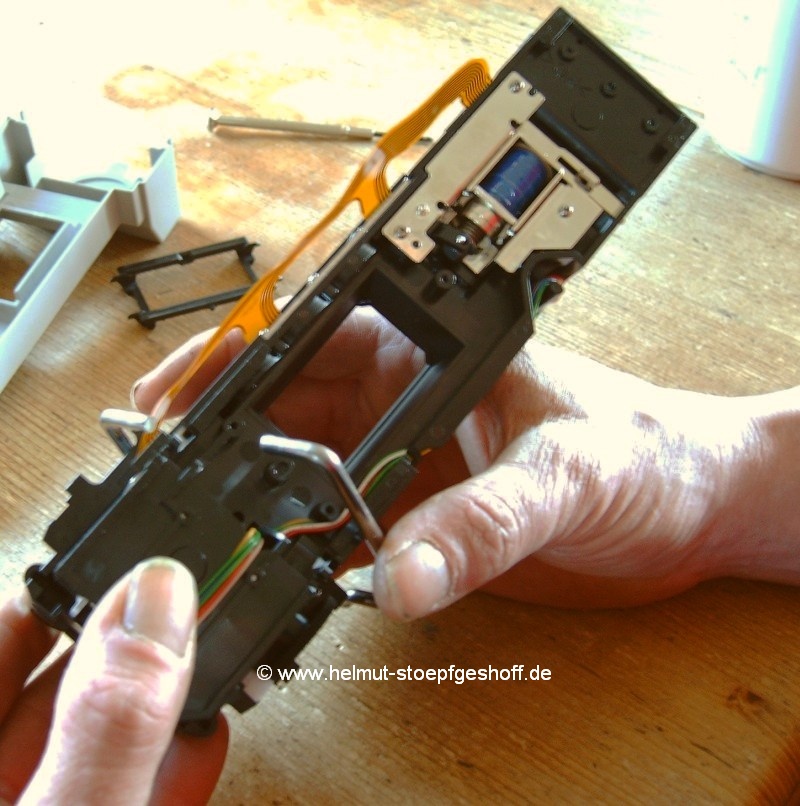

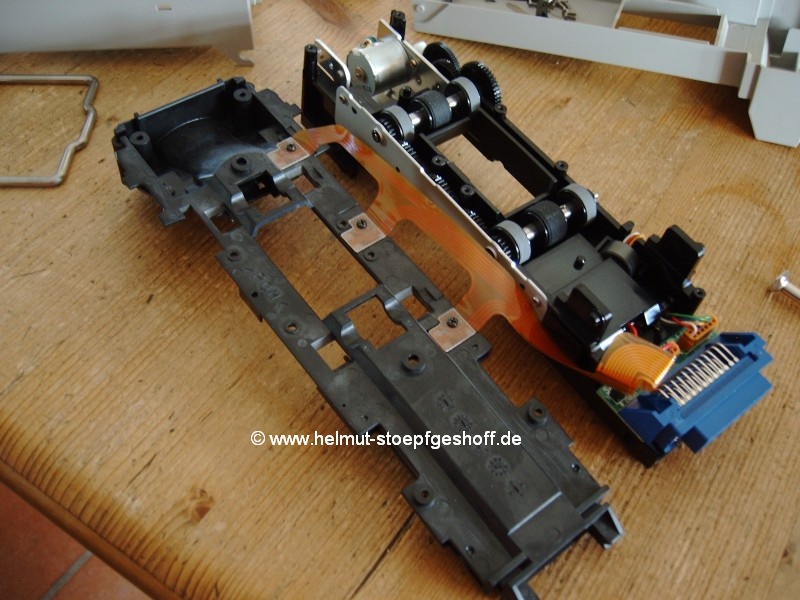

Next, turn over the chassis and remove the eight

screws, as shown in pictures 9-16. Caution! Be especially careful

with the two screws left and right from the light sensor, at the edge

of the scanning

opening (Pictures 14-15). If your screwdriver

slips at this point, there is a good chance that you will destroy your

light sensor! Next, turn over the chassis and remove the eight

screws, as shown in pictures 9-16. Caution! Be especially careful

with the two screws left and right from the light sensor, at the edge

of the scanning

opening (Pictures 14-15). If your screwdriver

slips at this point, there is a good chance that you will destroy your

light sensor!

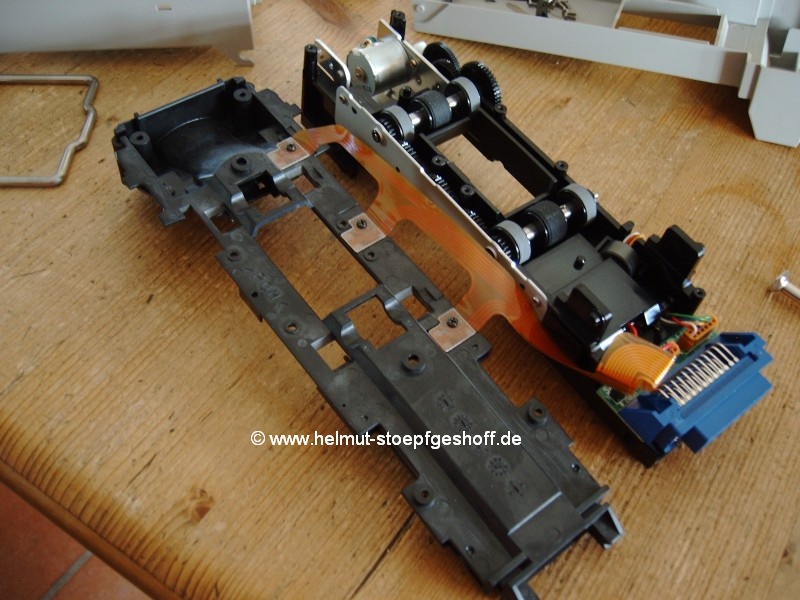

After

all eight screws have been removed, the complete film transport

assembly can

be lifted up, flipped over, and placed next to adaptor chassis. After

all eight screws have been removed, the complete film transport

assembly can

be lifted up, flipped over, and placed next to adaptor chassis.

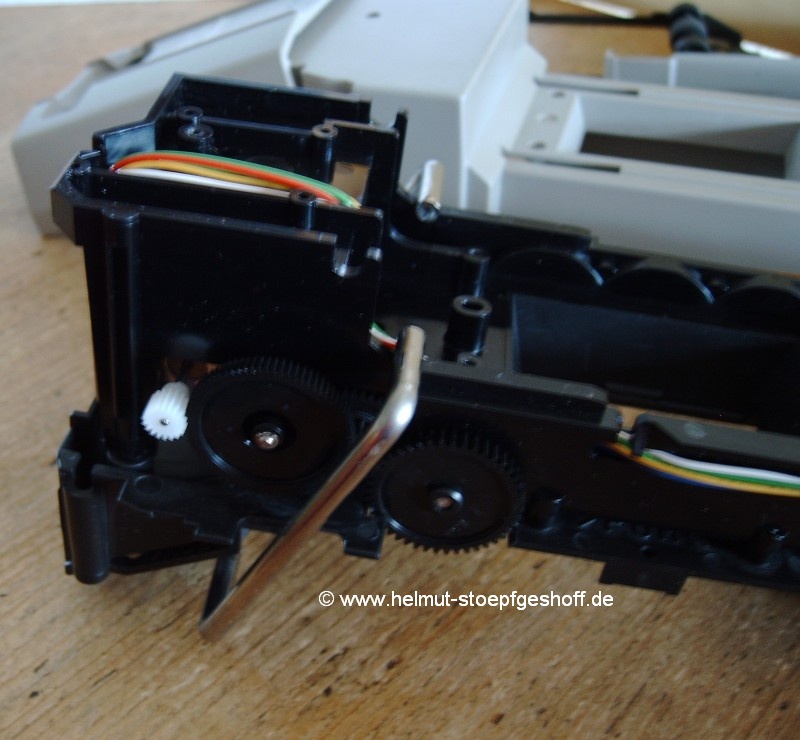

You can see the three light-sensors which are attached with

a screw to the underside of the film transport assembly, or more

precisely, you can see the flexible printed circuit board which is

soldered to the

light-sensors. You do not need to be overly concerned with this

flexible printed circuit board, as it is very robust. It can be

twisted around without

problem, as long as it is not jerked or folded.

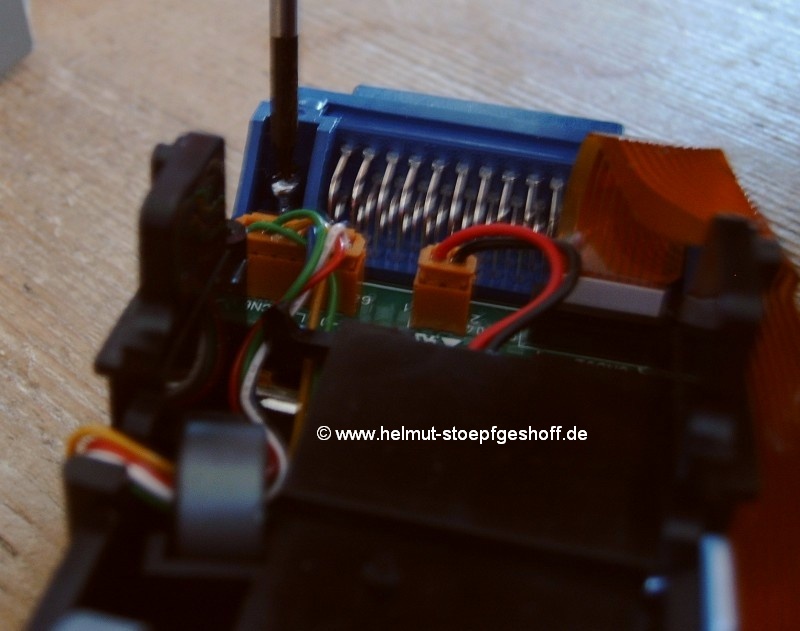

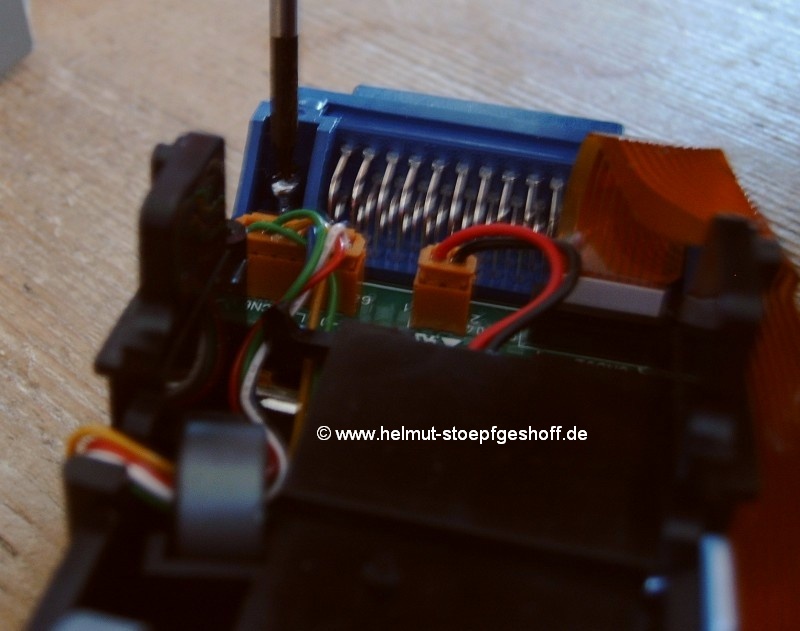

The

plugs that connect the “transport-motor” and the “lock out magnet” to

the hard circuit board should NOT be removed. These plugs are

very

small, and they are barbed very difficult. There is also the

risk of creating hairline fractures in the circuit board. The

plugs that connect the “transport-motor” and the “lock out magnet” to

the hard circuit board should NOT be removed. These plugs are

very

small, and they are barbed very difficult. There is also the

risk of creating hairline fractures in the circuit board.

For the same reasons, the flexible printed circuit board should also

not be unplugged -

the flexible printed circuit board can gently be twisted around as

movement is required.

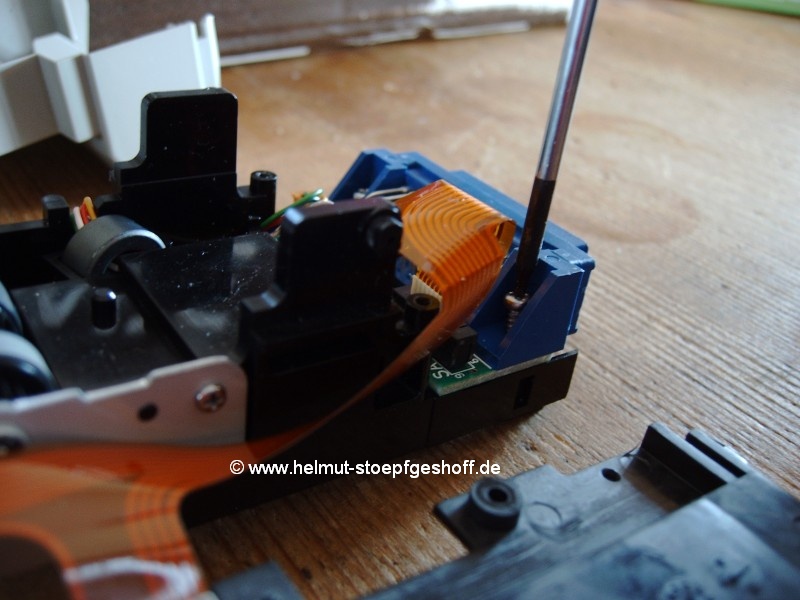

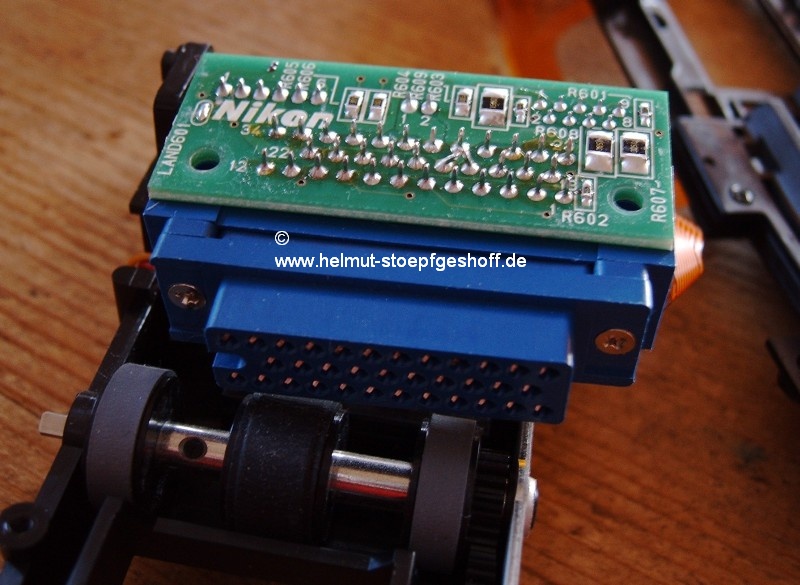

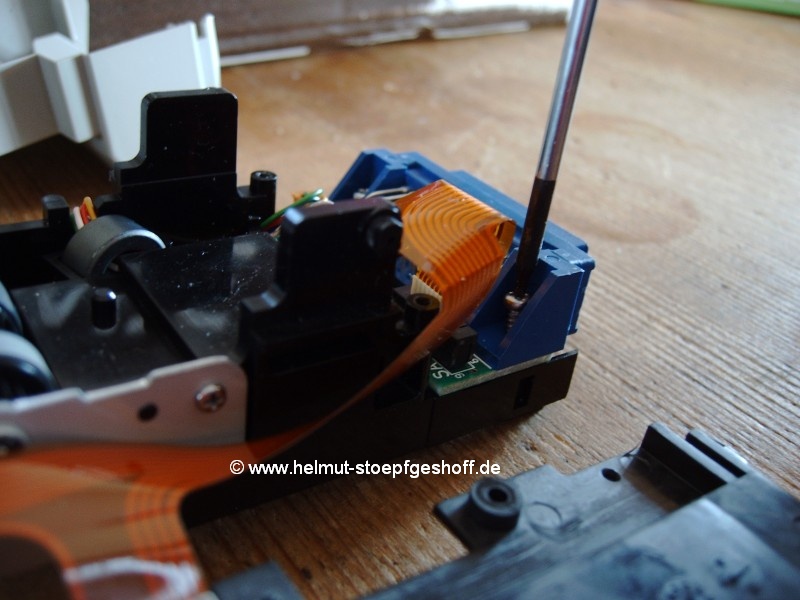

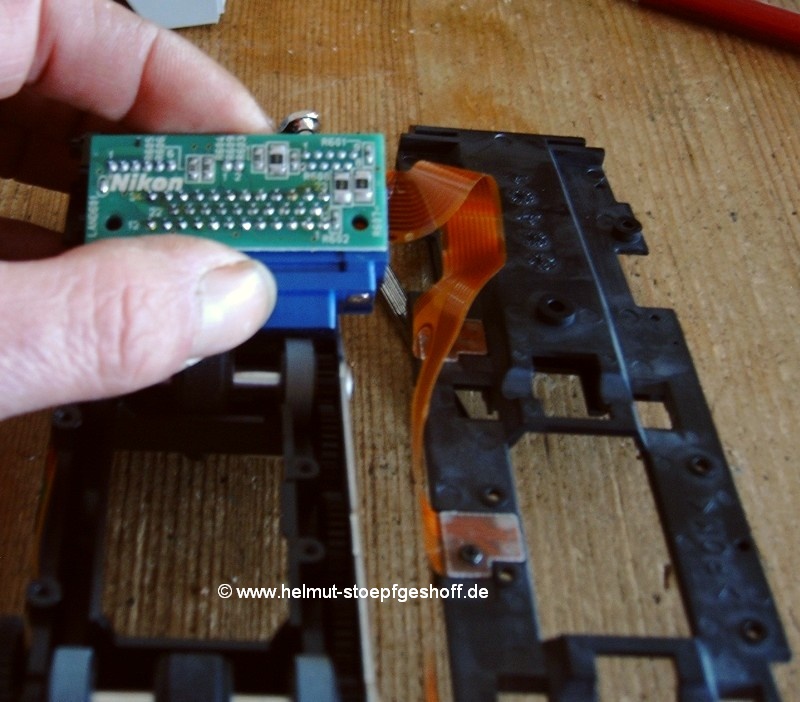

With

the larger Philips screwdriver, unscrew the two screws attaching the

blue

connector block and the hard circuit board to the chassis of the

adaptor. The

blue connector block and the circuit board underneath are joined

together. With

the larger Philips screwdriver, unscrew the two screws attaching the

blue

connector block and the hard circuit board to the chassis of the

adaptor. The

blue connector block and the circuit board underneath are joined

together.

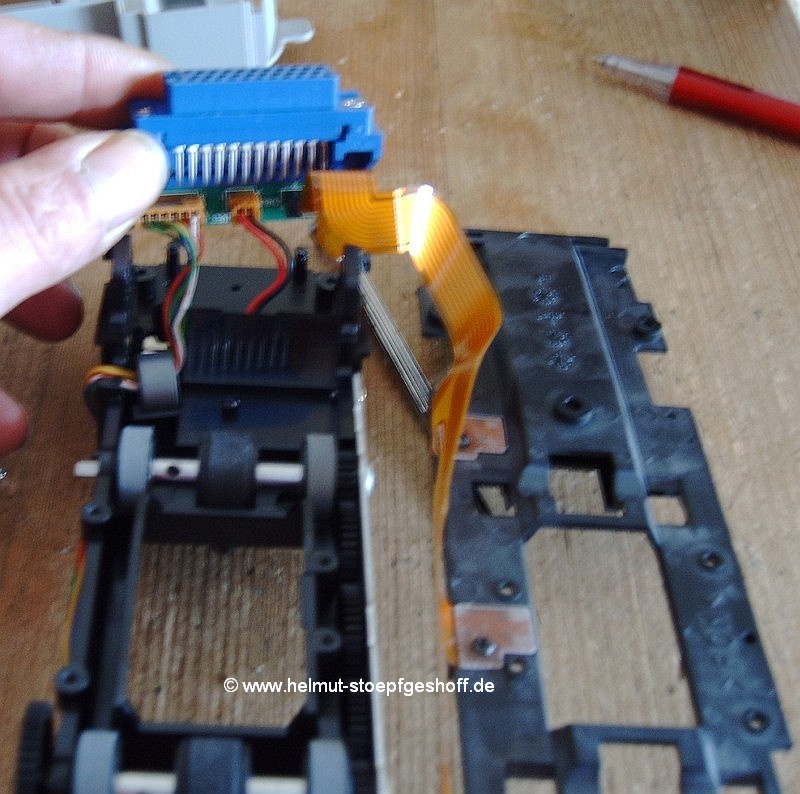

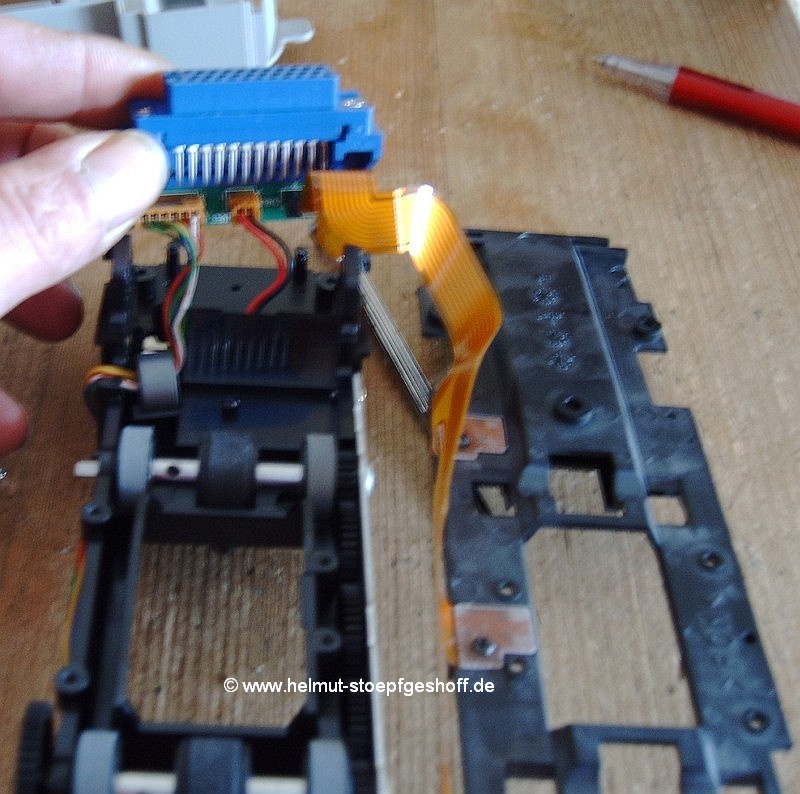

After

this

unit has been removed, unhook the cable which leads to the motor from

the chassis.

The circuit board and blue connector can now be flipped over 180

degrees. The under-side of the hard circuit board is now visible. After

this

unit has been removed, unhook the cable which leads to the motor from

the chassis.

The circuit board and blue connector can now be flipped over 180

degrees. The under-side of the hard circuit board is now visible.

You are now ready to begin the real part of the

modification.

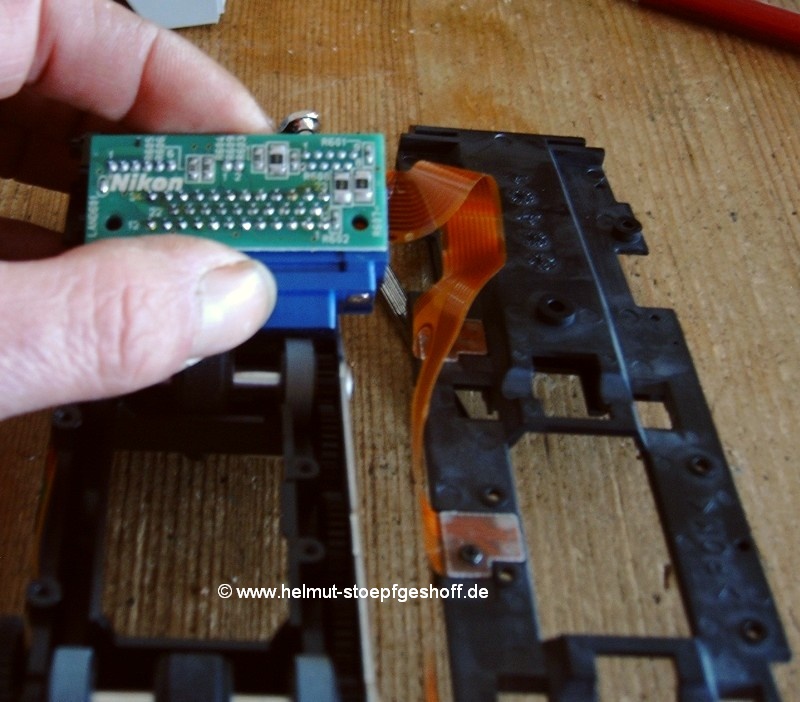

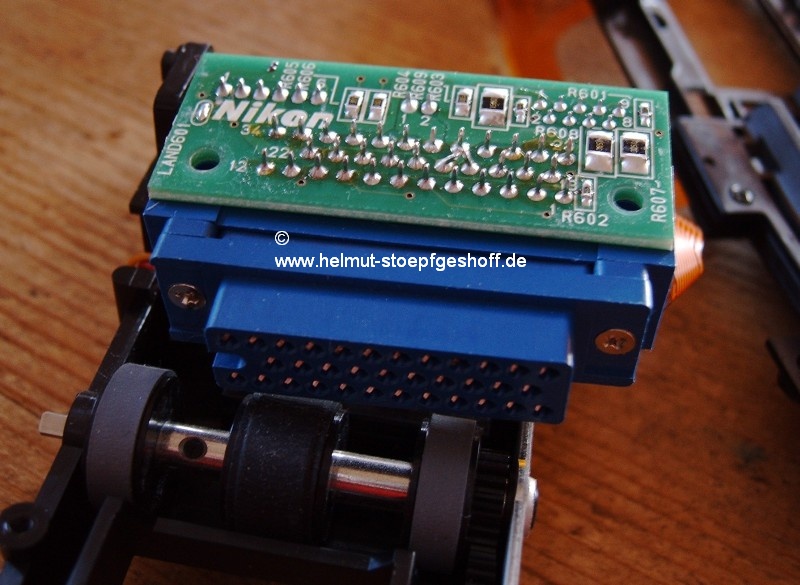

On the

hard circuit board, find the three contact rows which attach the blue

connector. In every row, there is a small number

printed into the circuit board. The contact next to each printed

number indicates the contact number. On the

hard circuit board, find the three contact rows which attach the blue

connector. In every row, there is a small number

printed into the circuit board. The contact next to each printed

number indicates the contact number.

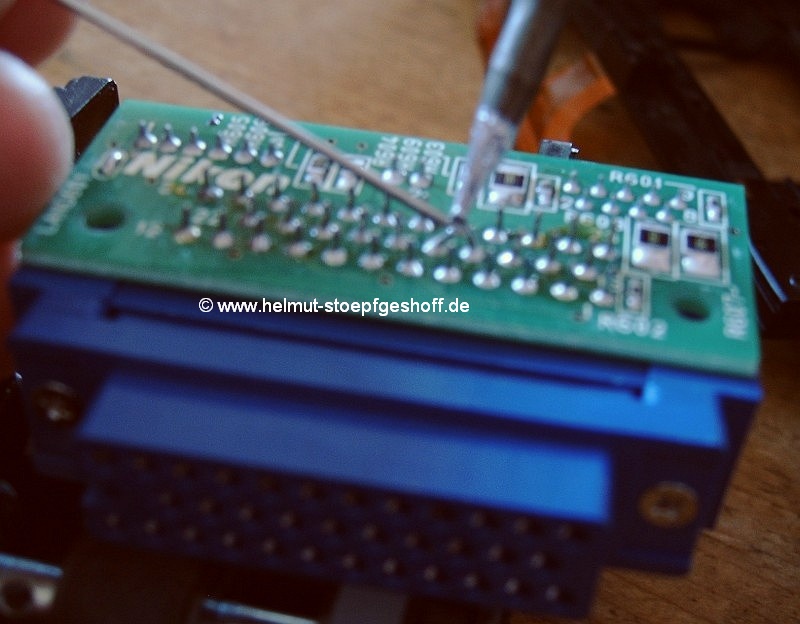

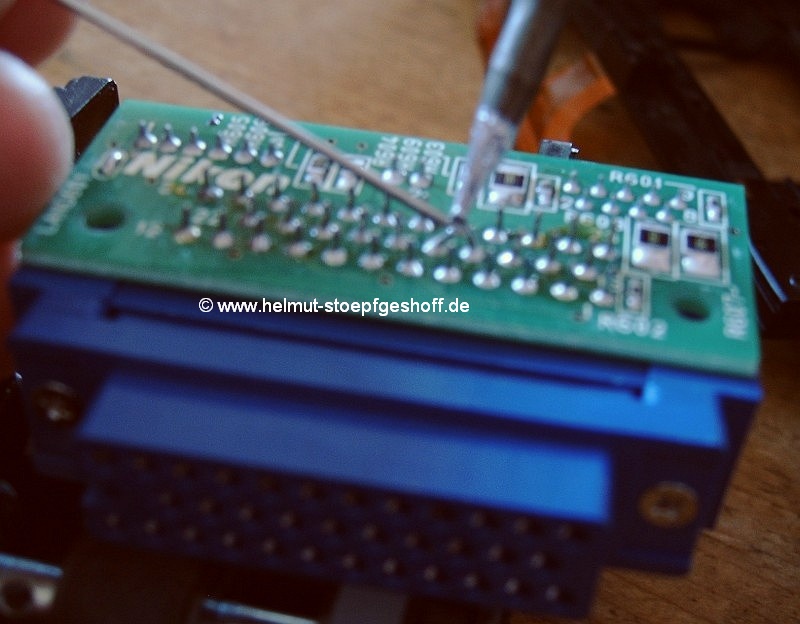

Contacts 16 and 17 have to be joined to each other. With

the blue connector block pointing towards you, these are the fourth

and the fifth contacts from the right hand side in the middle row.

Take the single

slit screwdriver and bend the two contacts ends towards each other, so

that

they touch or almost touch each other.

A little force might be needed, but there is no need to worry about

damage. Be careful that you bend the correct

two contacts, and that the others are not bent. Possible

fractures in the

soldercan be corrected in the next stage.

Take your small soldering iron and solder together

only the tips of these two bent contacts. Touch the soldering iron tip

on the

contacts until the solder on the bottom of the contacts become slightly

liquid. At

this point, apply a little more solder to the top of the contacts in

order to form a bridge at the top. Take your small soldering iron and solder together

only the tips of these two bent contacts. Touch the soldering iron tip

on the

contacts until the solder on the bottom of the contacts become slightly

liquid. At

this point, apply a little more solder to the top of the contacts in

order to form a bridge at the top.

Reassemble (remember to take care

with the fragile film sensor, and your flexible circuit board when

sliding the chassis into its grey shell), and there you go!

Your

SA-21 can now fulfill all of the functions of the SA-30 adaptor.

Please continue to read these

instructions,

as they contains further important tips.

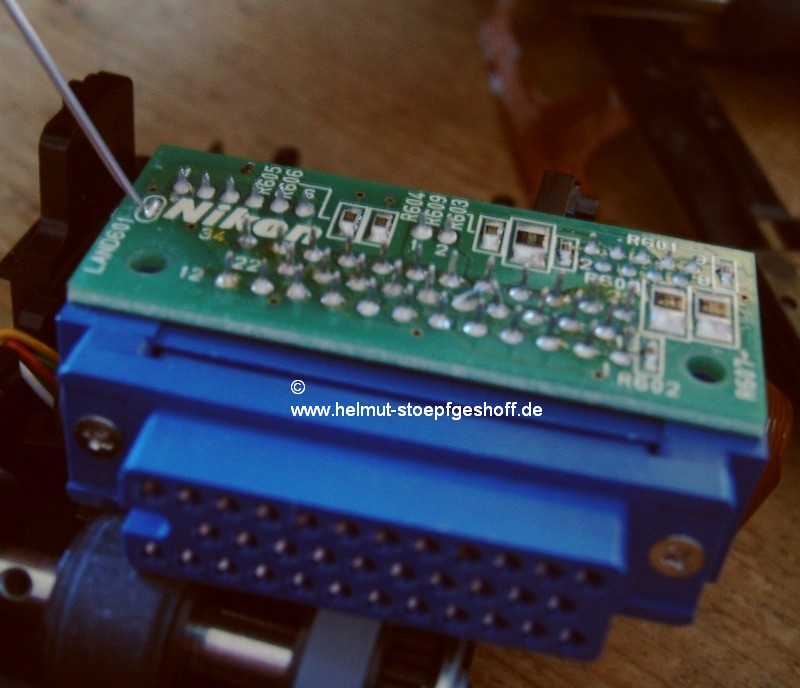

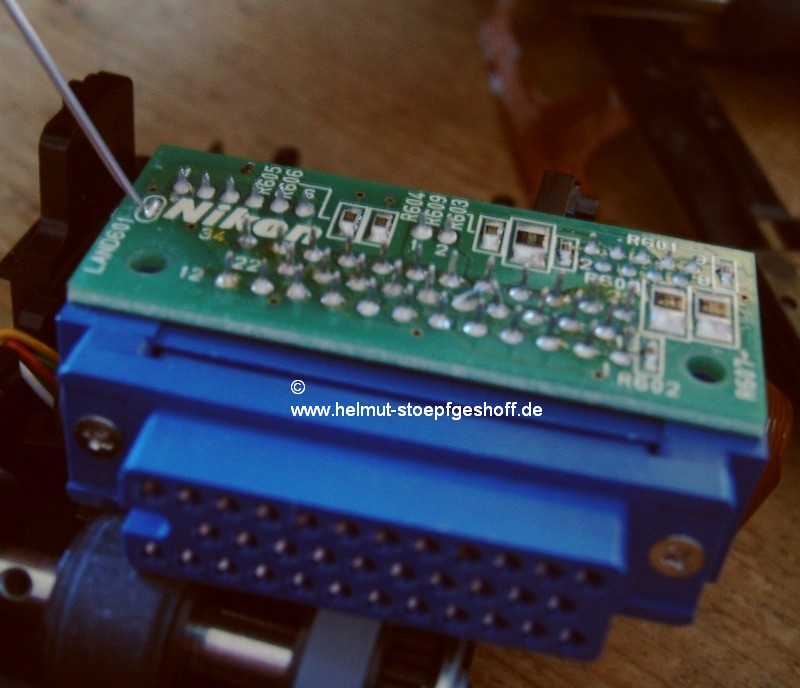

Nikon, or myself, would solder the contact bridge in a

different place. I have purposely chosen this solution for users

of this manual, who might not possess the expertise ore

equipment. For more experienced users, however, the originally

designed position is shown in the last picture.

Under

the finished bridge, shown in the

last picture, there are two very small soldering-tracks. Under

the finished bridge, shown in the

last picture, there are two very small soldering-tracks.

Please only solder at this point if

you have both the necessary equipment and experience….

At this point, I would like to explain a little about

the reassembling of the adaptor.

Please do not tighten all screws as tightly as they were

beforehand. The screws were originally tightened by a high speed

machine, which caused them to become quite hot. Because of this

heat, the screws had been slightly melted into their fitting

points.

This explains why they felt so tight to unscrew.

I also recommend thoroughly dusting down all components before putting

the

adaptor back together. Make sure that you only use a very soft

brush or blower when doing this. Be particularly careful when

dusting

the lens of the light-sensors.

There is NO need to oil or lubricate the

moveable components in any way….

Only test your adaptor after it has been

completely reassembled. Even if only the top plate has not

been re-attached, the adaptor will not work well in your scanner…

I hope that your modification has been completely successful, and that

you

can now enjoy the improvements you have made your adaptor.

In concluding, you are welcome to read my Notes

for the safe using

of your modified SA-21 adaptor or have a look on the download site.

If you have any questions, please contact me by

e-mail

But please note that my English isn't good enough for long messages

with

a lot of confusing technical words ;-(

(unclickable for obvious reasons)

special thanks to: Rupert Gillet for the excellent translation at

very short notice, and Lex Mrocki for tecnical cleaning!

Up to

the Top

|

|

3/ Carefully lever the top roller assembly (the

bridge) from its hinge pin and keep it safe for

later. This “bridge” has an open slit in the hinge-socket which

allows

you to remove it easily from the pin. Note - do not bend the “bridge”

out of

shape or it may not align back to the hinge-pins.

3/ Carefully lever the top roller assembly (the

bridge) from its hinge pin and keep it safe for

later. This “bridge” has an open slit in the hinge-socket which

allows

you to remove it easily from the pin. Note - do not bend the “bridge”

out of

shape or it may not align back to the hinge-pins.

You will need to remove the angled metal strips (pressure springs)

located above and below the scanning hole.

You will need to remove the angled metal strips (pressure springs)

located above and below the scanning hole. 5/

Now

you can remove the loading track. Please look very carefully at

the loading track, at the pins on the right and the left hand side,

which hold the track in place. They are different sizes. This

means

that it only fits in one way.

5/

Now

you can remove the loading track. Please look very carefully at

the loading track, at the pins on the right and the left hand side,

which hold the track in place. They are different sizes. This

means

that it only fits in one way.  Now

you can see that the locking bar for the top roller bridge is open at

the

bottom. Pivot the bar (as if in roller assembly "open" position), and

lift the bar so both hinge ends come out of their pivoting socket

toward the direction of the smaller end of the adaptor. At the same

time, turn the “bracket” a little so that it can be

released from its tilt limit guides.

Now

you can see that the locking bar for the top roller bridge is open at

the

bottom. Pivot the bar (as if in roller assembly "open" position), and

lift the bar so both hinge ends come out of their pivoting socket

toward the direction of the smaller end of the adaptor. At the same

time, turn the “bracket” a little so that it can be

released from its tilt limit guides.

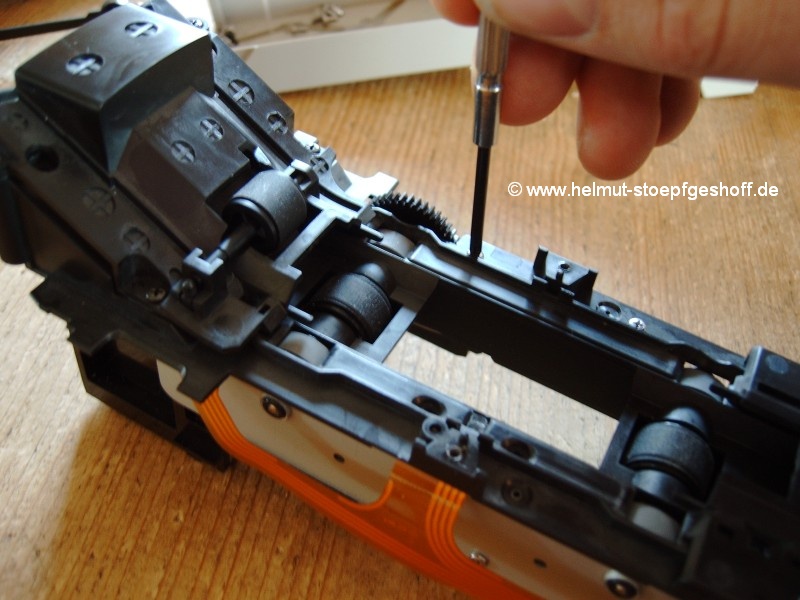

Next, turn over the chassis and remove the eight

screws, as shown in pictures 9-16. Caution! Be especially careful

with the two screws left and right from the light sensor, at the edge

of the scanning

opening (Pictures 14-15). If your screwdriver

slips at this point, there is a good chance that you will destroy your

light sensor!

Next, turn over the chassis and remove the eight

screws, as shown in pictures 9-16. Caution! Be especially careful

with the two screws left and right from the light sensor, at the edge

of the scanning

opening (Pictures 14-15). If your screwdriver

slips at this point, there is a good chance that you will destroy your

light sensor!

After

all eight screws have been removed, the complete film transport

assembly can

be lifted up, flipped over, and placed next to adaptor chassis.

After

all eight screws have been removed, the complete film transport

assembly can

be lifted up, flipped over, and placed next to adaptor chassis. The

plugs that connect the “transport-motor” and the “lock out magnet” to

the hard circuit board should NOT be removed. These plugs are

very

small, and they are barbed very difficult. There is also the

risk of creating hairline fractures in the circuit board.

The

plugs that connect the “transport-motor” and the “lock out magnet” to

the hard circuit board should NOT be removed. These plugs are

very

small, and they are barbed very difficult. There is also the

risk of creating hairline fractures in the circuit board.

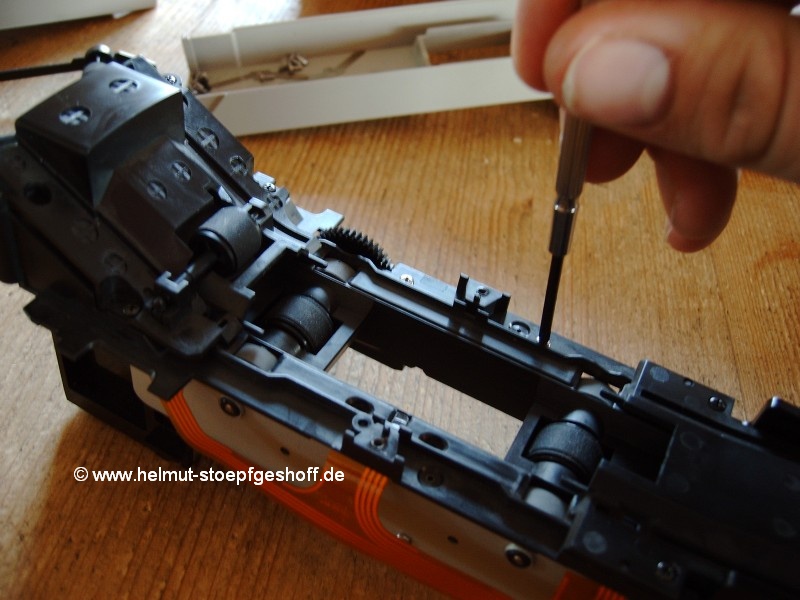

With

the larger Philips screwdriver, unscrew the two screws attaching the

blue

connector block and the hard circuit board to the chassis of the

adaptor. The

blue connector block and the circuit board underneath are joined

together.

With

the larger Philips screwdriver, unscrew the two screws attaching the

blue

connector block and the hard circuit board to the chassis of the

adaptor. The

blue connector block and the circuit board underneath are joined

together.

After

this

unit has been removed, unhook the cable which leads to the motor from

the chassis.

The circuit board and blue connector can now be flipped over 180

degrees. The under-side of the hard circuit board is now visible.

After

this

unit has been removed, unhook the cable which leads to the motor from

the chassis.

The circuit board and blue connector can now be flipped over 180

degrees. The under-side of the hard circuit board is now visible.

On the

hard circuit board, find the three contact rows which attach the blue

connector. In every row, there is a small number

printed into the circuit board. The contact next to each printed

number indicates the contact number.

On the

hard circuit board, find the three contact rows which attach the blue

connector. In every row, there is a small number

printed into the circuit board. The contact next to each printed

number indicates the contact number. Take your small soldering iron and solder together

only the tips of these two bent contacts. Touch the soldering iron tip

on the

contacts until the solder on the bottom of the contacts become slightly

liquid. At

this point, apply a little more solder to the top of the contacts in

order to form a bridge at the top.

Take your small soldering iron and solder together

only the tips of these two bent contacts. Touch the soldering iron tip

on the

contacts until the solder on the bottom of the contacts become slightly

liquid. At

this point, apply a little more solder to the top of the contacts in

order to form a bridge at the top. Under

the finished bridge, shown in the

last picture, there are two very small soldering-tracks.

Under

the finished bridge, shown in the

last picture, there are two very small soldering-tracks.